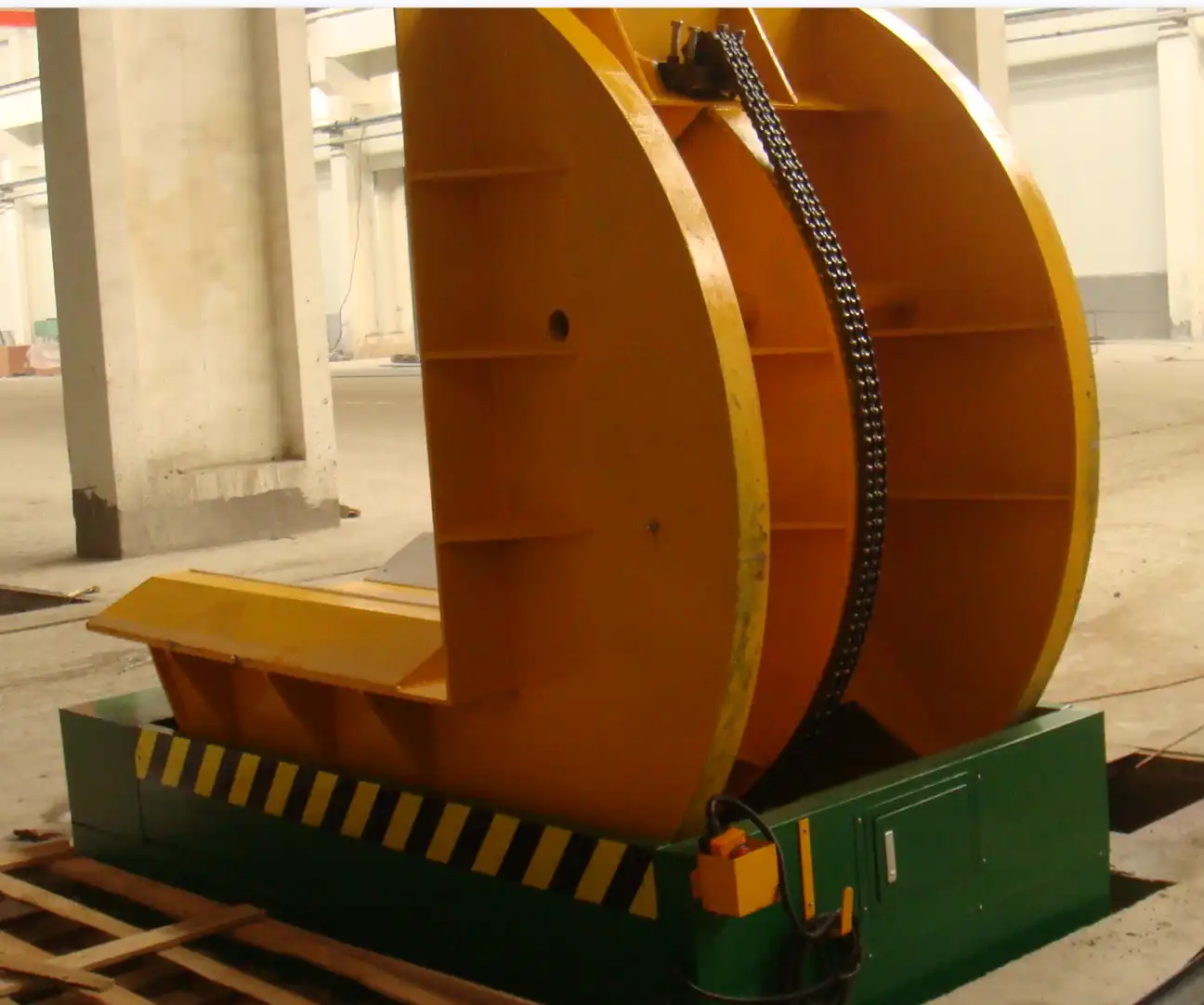

In the bustling world of modern manufacturing, efficiency and safety are the twin pillars of success. Enter the coil upender machine—a marvel of engineering designed to make life easier within industries reliant on heavy coils of metal, plastic, or other materials. Picture a facility where massive coils, weighing several tons, need to be rotated from a vertical to a horizontal position or vice versa. Manhandling such giants seems implausible, not to mention hazardous. This is where the coil upender machine elegantly steps in, ensuring the seamless transition of coils with precision and safety, minimizing human error and injury.

One might wonder, why is there such a buzz about coil upender machines? Let's take a journey through their advantages. Imagine a scenario within a steel processing plant where the daily task involves turning and positioning steel coils weighing up to 20,000 pounds. With a coil upender, what used to take hours of labor can be accomplished in minutes, improving throughput and operational efficiencies significantly. Studies have shown that facilities adopting these machines report a 40% reduction in handling time and a notable increase in workforce safety.

The tactile relief of a smooth operational flow fueled by innovation sparks interest. Reflect on the implications of integrating such machinery—not only reducing physical strain on workers but also bolstering precision, thereby curtailing waste and maintenance costs. Curiosity tingles at the thought of how these machines transform the workplace environment and productivity metrics. Could the coil upender be the unsung hero in industrial automation?

Claim: The coil upender machine is indispensable for industries that handle large coils, offering enhanced safety, efficiency, and precision. Its integration into manufacturing processes is not just beneficial but crucial for optimizing performance and safeguarding workers.

How Does a Coil Upender Machine Enhance Workplace Safety?

Safety remains a paramount concern in any industrial setup. Consider the daunting task faced by steel mill workers as they attempt to manually reposition heavy coils. This process poses a significant risk of bodily injury, from musculoskeletal disorders to severe accidents caused by dropped loads. By incorporating a coil upender machine into operations, these risks are drastically mitigated. The machine effortlessly handles the heft, executing a perfect rotation while keeping human operators at a safe distance. No more strained backs or dangerous slips; these machines do the heavy lifting with poise and precision.

It's not only about preventing injuries but also about fostering a culture of safety. When employees see that their company invests in technology to minimize risks, morale and trust skyrocket. Workers feel valued and empowered, knowing they aren't expected to perform unsafe manual handling tasks. A safer environment translates to fewer lost workdays, reducing downtime and associated costs.

Furthermore, the precision of a coil upender means that coils are less likely to be damaged during handling. Picture a scenario where a coil slips from a poorly controlled manual rotation, leading to unsightly dents and potentially costly damage. The coil upender eliminates this risk, ensuring each transition is smooth and controlled, preserving the coil's integrity.

The coil upender machine's contribution to workplace safety is further supported by its compliance with industry safety standards. Designed with features such as anti-skid surfaces and secure locking mechanisms, these machines align with regulations aimed at safeguarding industrial environments.

What Are the Efficiency Gains from Utilizing a Coil Upender Machine?

Efficiency permeates every aspect of industrial operations. A coil upender machine offers profound efficiency gains by transforming the coil handling process. Consider a typical manufacturing facility handling a dozen coils daily. With manual handling, each coil's repositioning could take an hour or more. With a coil upender, that process becomes almost instant, reducing the repositioning time to a matter of minutes.

To visualize the efficiency, here's some supportive data:

| Method | Time per Coil | Coils per Day |

|---|---|---|

| Manual Handling | 60 minutes | 6 coils |

| Coil Upender | 15 minutes | 24 coils |

The stark contrast in productivity is evident. With a coil upender, a facility can handle four times the number of coils in the same period, dramatically enhancing throughput and optimizing resource allocation. These machines enable a more strategic workforce deployment, allowing employees to focus on tasks that require human insight and creativity, rather than mundane, labor-intensive coil handling.

Beyond time savings, the reduction of human errors is another remarkable efficiency gain. A coil upender ensures precise positioning and reduces the likelihood of mishaps that could disrupt the production line. Moreover, the machine's automation reduces variability in task execution, ensuring consistent output quality.

Efficiency isn't merely about speed; it's also about optimizing the use of available resources. By eliminating the need for multiple workers to handle a single coil, companies can allocate their human resources more effectively, leading to overall company growth and innovation.

What Role Do Coil Upender Machines Play in Cost Reduction?

The financial implications of integrating coil upender machines are significant. Initially, the investment might seem considerable, but the return on investment (ROI) proves compelling over time. Think about the costs linked to workplace injuries—medical expenses, workers' compensation, and potential litigation. Minimizing these costs by ensuring a safer work environment is financially prudent.

Consider the following data illustrating the cost savings:

| Expense Type | With Manual Handling | With Coil Upender |

|---|---|---|

| Workplace Injuries | $50,000 annually | $5,000 annually |

| Equipment Damage | $20,000 annually | $2,000 annually |

| Productivity Loss | $30,000 annually | $10,000 annually |

In addition to reduced injury-related costs, equipment damage is minimized. Coils that are mishandled can incur damage, leading to costly repairs or replacements. The precision of a coil upender reduces these incidents, preserving both the coils' condition and the machinery's longevity.

Another area of cost savings is associated with labor. By streamlining the coil handling process, fewer workers are needed for this specific task, allowing companies to reallocate manpower to other areas that could drive growth and innovation.

What Are the Misconceptions About Coil Upender Machines?

It's easy to get swept up in the excitement of new technology, but some misconceptions about coil upender machines persist. One common belief is that these machines are only suitable for large-scale operations. While it's true that big facilities with high throughput can gain significant benefits, smaller operations can also enjoy enhanced safety, efficiency, and cost savings.

Another misconception is that the machines are complex to operate, requiring extensive training. However, most modern coil upenders are designed with user-friendliness in mind. Operators can quickly learn to use these machines, with intuitive controls and comprehensive safety features.

True Fact: Coil upender machines significantly reduce the risk of workplace injuries, contributing to safer work environments.

False Fact: Coil upender machines are exclusively beneficial for large industrial operations, with no advantages for smaller businesses.

How Do Industry Dynamics Influence the Adoption of Coil Upender Machines?

The adoption of coil upender machines is influenced by evolving industry dynamics. As manufacturing and processing industries face increased pressure to optimize efficiency while maintaining safety standards, integrating advanced machinery like coil upenders becomes a strategic imperative. Industries such as automotive, aerospace, and metal processing have seen the profound impact of these machines on their operations.

Consider the automotive sector, where precision and speed are critical. Coil upender machines enable rapid and accurate repositioning of coils, ensuring uninterrupted production lines and maintaining high-quality standards. These machines align perfectly with the industry's demand for reliability and consistency.

Moreover, as regulatory standards for workplace safety become more stringent, companies are compelled to seek solutions that ensure compliance. Coil upender machines provide a tangible means to meet these requirements, reducing the risk of penalties and enhancing brand reputation.

Industry trends indicate a growing preference for automation and smart manufacturing solutions. Coil upender machines fit seamlessly into this narrative, exemplifying the trend toward leveraging technology for competitive advantage. As more industries recognize their potential, the adoption rate is expected to rise, reshaping the landscape of coil handling.

What Are the Specific Industry Applications of Coil Upender Machines?

The versatility of coil upender machines extends across various industries, each benefiting uniquely from this technology. In the metal processing industry, these machines handle steel, aluminum, and copper coils with precision, streamlining operations and reducing material handling errors. In the plastics industry, coil upenders efficiently manage large rolls of materials, ensuring smooth transitions and minimizing damage.

Here's a glimpse at industry-specific data:

| Industry | Materials Handled | Efficiency Improvement |

|---|---|---|

| Metal Processing | Steel, Aluminum | 35% faster |

| Plastics Manufacturing | Polyethylene, PVC | 30% reduction in waste |

| Textile Production | Cotton, Polyester | 25% increase in productivity |

In textile production, coil upenders facilitate the handling of fabric rolls, ensuring seamless integration into assembly lines. This application leads to a notable productivity boost, as demonstrated by the 25% increase in output.

How Can a Business Maximize the Benefits of Coil Upender Machines?

To fully capitalize on the benefits of coil upender machines, businesses should focus on strategic integration and employee training. Conducting a thorough assessment of current operations can identify areas where coil upenders can be most impactful. Once integrated, ongoing analysis of efficiency gains and cost reductions will ensure continued optimization.

Employee training is crucial for maximizing the potential of these machines. Providing comprehensive training programs ensures operators understand the machine's features and safety protocols, reducing the risk of accidents and guaranteeing smooth operation. Moreover, involving employees in the integration process fosters a sense of ownership and responsibility.

Regular maintenance is also essential for maximizing the coil upender's lifespan. Routine inspections, cleaning, and servicing keep the machine running efficiently, reducing the likelihood of unexpected breakdowns.

Finally, businesses should explore opportunities for customization. Many manufacturers offer tailored solutions to cater to specific needs, ensuring the coil upender fits seamlessly into existing workflows.

Conclusion

In conclusion, coil upender machines are transformative in the manufacturing world, offering key benefits such as enhanced safety, increased efficiency, and significant cost savings. Their adoption across various industries marks a vital step toward achieving operational excellence and maintaining competitive advantage. The Claim remains that coil upender machines are not merely beneficial but essential for optimizing industrial processes and safeguarding workers' well-being.

More machines for the: coil upenders