Finding the right coil upender for sale can feel like searching for a needle in a haystack. These heavy-duty machines play a crucial role in industries such as metalworking, manufacturing, and logistics. They make the process of handling and repositioning large coils significantly easier. But with so many different models and sellers on the market, pinpointing the right one can be both complex and time-consuming.

Many industries, from automotive to construction, rely heavily on coil upenders to enhance safety and efficiency. For instance, the global industrial machinery market was valued at over $700 billion in 2021, a testament to the critical role these machines play in modern production lines. With this widespread use, demand for reliable and durable coil upenders continues to rise.

However, the question remains: where does one even start looking for such a specialized piece of equipment? The hunt can be daunting, yet incredibly rewarding once you land the perfect deal.

Claim: The search for a coil upender for sale is a vital endeavor for businesses aiming to optimize their material handling processes and ensure workplace safety.

Why is a Coil Upender Necessary for Industrial Use?

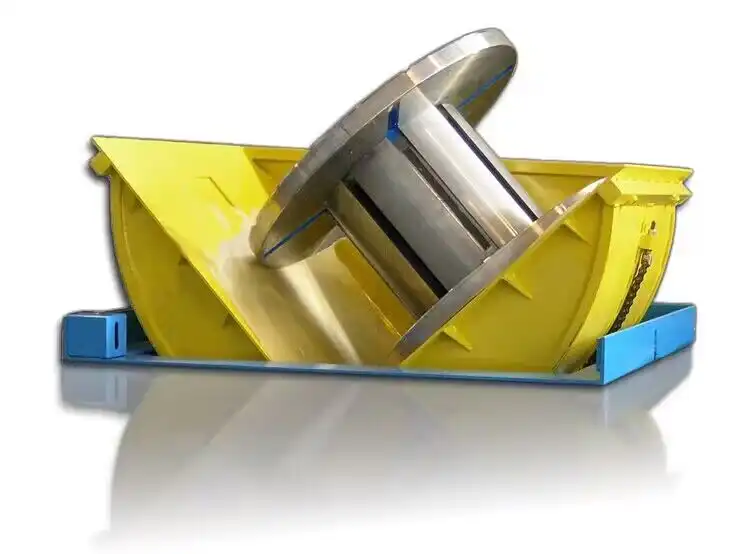

For industries dealing with heavy coils, such as those in metalworking or manufacturing, coil upenders are indispensable. Imagine trying to manually lift and reposition steel coils that weigh thousands of pounds—it’s not only impractical but also a major safety hazard. Coil upenders come to the rescue by enabling operators to turn coils safely and efficiently.

Consider a scenario in a steel manufacturing plant. The operator needs to rotate a massive coil from horizontal to vertical or vice versa. Without a coil upender, this task would require multiple workers and still pose a significant risk of injury or damage. The machine, however, executes this task smoothly with minimal human intervention, enhancing both safety and productivity.

In addition, coil upenders play a crucial role in minimizing downtime. By facilitating quick and easy repositioning of coils, they help maintain an uninterrupted workflow. This reduction in idle time contributes significantly to a company’s bottom line, making the investment in a coil upender a smart financial decision.

But how do you choose the right coil upender in a market flooded with options? The answer lies in understanding the specific needs of your operation. Each model comes with its unique set of features, catering to different capacities, sizes, and functionalities.

What are the Top Platforms for Purchasing Coil Upenders?

When looking to buy a coil upender, certain platforms stand out for their variety and reliability. Online marketplaces like Alibaba and eBay offer a wide range of options, from brand-new to pre-owned machines. These platforms provide detailed listings, complete with specifications, prices, and seller ratings, allowing buyers to make informed decisions.

Moreover, specialized industrial equipment websites often have dedicated sections for coil upenders. Businesses like APT Systems and Konecranes not only sell these machines but also provide valuable insights and customer support to help you choose the right model for your needs.

Local equipment dealers can also be a viable option. These dealers frequently have used or refurbished machines at competitive prices, and they offer the advantage of in-person inspections and consultations. Furthermore, purchasing locally can reduce shipping costs and lead times.

Comparison of Coil Upender Sellers

| Platform | Variety | Customer Support |

|---|---|---|

| Alibaba | Wide | Moderate |

| eBay | Moderate | Low |

| APT Systems | Limited | High |

| Konecranes | Moderate | High |

| Local Dealers | Varies | High |

How Do You Assess the Quality of a Coil Upender?

Quality assessment of a coil upender necessitates a keen eye for detail and a comprehensive understanding of industrial machinery. Critical factors to consider include material construction, load capacity, and operational features. A robust coil upender should be made from high-grade steel or similar durable materials to withstand the rigors of industrial use.

Load capacity is another essential consideration. A coil upender’s ability to handle a particular coil size and weight is crucial to ensuring efficiency and safety. For instance, a unit with a load capacity of 20,000 pounds will be necessary for heavy-duty industrial operations, whereas smaller capacities might suffice for lighter materials.

Operational features such as ease of control, safety mechanisms, and maintenance requirements also play a significant role. Machines equipped with user-friendly controls and automated safety features can significantly reduce training time and potential mishaps.

Finally, manufacturer reputation and warranty offerings provide peace of mind. Reputable manufacturers are more likely to stand by their products and offer comprehensive warranties, reducing the risk associated with the purchase.

Load Capacities of Coil Upenders

```html

| Model | Load Capacity (lbs) | Material |

|---|---|---|

| Model A | 10,000 | Steel |

| Model B | 15,000 | Aluminum |

| Model C | 20,000 | Steel |

| Model D | 25,000 | Steel |

| Model E | 30,000 | Composite |

```

Are There Hidden Costs Associated with Coil Upenders?

While the sticker price of a coil upender is the most apparent expense, several hidden costs can impact the total investment. Shipping and installation are often overlooked but can add significantly to the overall price, especially for large or overseas purchases.

Maintenance is another crucial factor. Regular servicing and potential repairs can accumulate over time, especially if the machine is used in demanding environments. Opting for a coil upender with accessible parts and a robust maintenance support network can mitigate these expenses.

Another less obvious cost is the potential need for facility modifications. Depending on the dimensions and operational requirements of the coil upender, adjustments to existing infrastructure might be necessary to accommodate the new equipment safely and efficiently.

Finally, training costs should not be underestimated. Ensuring staff are properly trained to operate the upender is crucial for safety and efficiency. Some sellers offer training as part of the purchase package, which can be a significant advantage.

How Do Industry Trends Impact Coil Upender Purchases?

The evolving landscape of industrial technology influences coil upender purchases significantly. With automation and Industry 4.0 gaining traction, there is a growing demand for smart coil upenders equipped with features such as remote monitoring and operation. These advancements not only improve efficiency but also provide valuable data insights for predictive maintenance and process optimization.

Consider the rise of sustainable practices in manufacturing. There’s an increasing emphasis on energy-efficient machinery that not only reduces operational costs but also aligns with corporate sustainability goals. Investing in a modern coil upender that consumes less energy can yield long-term savings and environmental benefits.

Furthermore, the global supply chain disruptions experienced in recent years highlight the need for equipment that enhances flexibility and resilience. Coil upenders that facilitate quick changeovers and adapt to varying coil specifications can be invaluable in such unpredictable times.

Industry Trends Data

| Year | Automation Adoption (%) | Energy Efficiency Focus (%) |

|---|---|---|

| 2019 | 40 | 25 |

| 2020 | 50 | 35 |

| 2021 | 60 | 45 |

| 2022 | 70 | 55 |

| 2023 | 80 | 65 |

What Are the Key Considerations for Ensuring a Successful Purchase?

Ensuring a successful coil upender purchase involves several key considerations, beginning with a thorough needs assessment. Understanding the specific requirements of your operation, such as load capacities, dimensions, and operational features, is critical.

Vendor reputation is equally important. Researching prospective sellers and choosing those with a proven track record of reliability and customer satisfaction can mitigate risks. Engaging with references and reading testimonials can provide valuable insights into the seller’s credibility and product quality.

Additionally, after-sales support is crucial. Investigate the level of support offered, including installation services, training, and maintenance packages. A seller who provides comprehensive post-purchase assistance can significantly enhance the value of your investment.

Finally, consider future scalability. Opt for a coil upender that not only meets current needs but also aligns with potential future growth or diversification of operations. This foresight can prevent costly equipment upgrades down the line.

True Fact and False Fact about Coil Upenders

True Fact: Coil upenders can significantly reduce workplace accidents related to the manual handling of heavy coils. By automating the repositioning process, they minimize the risk of strains, falls, and equipment damage, contributing to a safer work environment.

False Fact: All coil upenders operate at the same speed and efficiency. In reality, different models come with varying operational speeds and features, impacting their suitability for various industrial applications. It’s essential to select a model that matches the specific demands of your operation to ensure optimal performance.

Conclusion

In conclusion, finding the right coil upender for sale involves more than just browsing online listings. It requires a comprehensive understanding of your industrial needs, a detailed assessment of potential sellers, and a keen awareness of industry trends. By considering factors such as quality, hidden costs, and vendor reputation, businesses can make informed decisions that enhance operational efficiency and safety.

Final Claim: Investing in the right coil upender is not merely a purchase but a strategic decision that can transform material handling processes, leading to significant long-term benefits.

More machines for the: coil upenders